INDUSTRIES WE PROTECT

High Risk Foods Manufacturing

Are pests in your high-risk food operation keeping you up at night? Pests left unchecked, will significantly amplify dangerous pathogens in your operation. We realize pest prevention is not something you wish to take lightly.

Pharmaceutical & Bio-Pharmaceutical Manufacturing

In a critical and detail-oriented industry, you need the same from your pest prevention. We are sensitive to your goals and objectives of protecting your crucial pharmaceutical products and brand, while staying compliant with cGMPs, The FDA, SOPs and your clients.

Bakery Manufacturing

Organically Certified Manufacturing

Heat signatures escaping along with delectable fragrances that naturally attract pests. Air borne ingredients such as flour, coating difficult to clean areas such as electrical panels and processing equipment. Are bakeries a pest's dream? Bakeries certainly offer a multitude of pest challenges.

Organically Certified Manufacturing

Organically Certified Manufacturing

Organically Certified Manufacturing

The end consumer who wishes to purchase organic foods is counting on you to ensure that pesticides do not come in contact with their food. How do you ensure your products are farm to fork Organic pure? How do your Organic Certifiers feel about your pest prevention program during your Certification Audit?

Medical Device Manufacturing

Organically Certified Manufacturing

Medical Device Manufacturing

One bit of foreign material shipped to your customers inside a heart catheter package would likely spell disaster for your organization. Small insect pests may just be that foreign material. In addition, strict compliance with cGMPs, your SOPs and FDA compliance, are likely critical to you.

Seafood Manufacturing

Organically Certified Manufacturing

Medical Device Manufacturing

Value added plant? Cutting and portioning only? IQF? No matter the type of seafood facility, there are unique pest challenges with each and every one.

Meat & Poultry Manufacturing

Meat & Poultry Manufacturing

Meat & Poultry Manufacturing

Having the U.S.D.A. residing in-house is a constant reminder that all prerequisite programs must be sound. Your pest prevention program should be in constant compliance. Flies, rodents and other pests in your processing areas could lead to a lengthy shut down.

Beverage Manufacturing

Meat & Poultry Manufacturing

Meat & Poultry Manufacturing

Whether you produce, store or handle juice, soda, energy drinks, wine, spirits, water or other beverages, customer complaints are likely at the top of your list of concerns. There are many ways things can go wrong with pest infiltration in beverage manufacturing facilities.

Dairy Manufacturing

Meat & Poultry Manufacturing

Warehousing & Logistics

Producing your micro-sensitive dairy products, safe and pure for the public is daunting enough. When pests that are pathogen laden invade your environment, your concern is compounded.

Warehousing & Logistics

Packaging (Food Contact & Non Food Contact) Manufacturing

Warehousing & Logistics

The complexities of food logistic / warehousing facilities can be daunting when it comes to pests. We have ways to simplify your pest prevention program to assist you in prioritizing your prevention efforts.

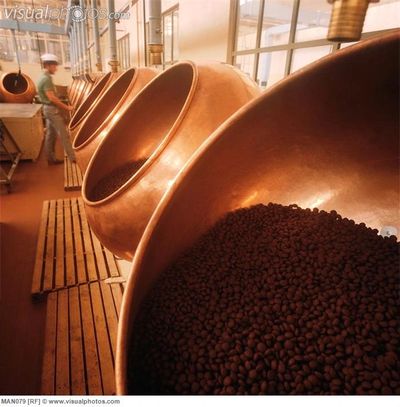

Candy Confectionery Sweet Snacks Manufacturing

Packaging (Food Contact & Non Food Contact) Manufacturing

Packaging (Food Contact & Non Food Contact) Manufacturing

Who enjoys candy more than we do? You guessed it, pests. Sanitation is difficult due to ingredients such sugars and butter fats when combined with difficult to clean equipment and surfaces. Your raw ingredients are always a challenge to maintain pest free.

Packaging (Food Contact & Non Food Contact) Manufacturing

Packaging (Food Contact & Non Food Contact) Manufacturing

Packaging (Food Contact & Non Food Contact) Manufacturing

Your packaging products are considered the same as the food and medicine they hold. Pests may cause issues with the customers you supply to. Food and medicine contact packaging is even more crucial to protect from contamination due to pests.

FDA, USDA, USDC, ISO2200, Organic, 3RD Party Audited

Your product safety and quality challenges are daunting every day. The last thing you need to worry about, are non-compliance and non-conformance due to pests, or due to less than adequate pest program compliance documentation and reporting.

As a niche and exclusive service provider to the food and medicine manufacturing industries, we have studied and catered to your unique and specific needs since 2013.

Our Founder created this company to help bridge the operational gaps that hinder excellence in pest prevention for the food and medicine manufacturing industries. He was convinced that an exclusive effort and focus were the best way to ensure that our customers are pest free and remain compliant with the regulations and standards they are facing day-to-day.

HIGH-RISK FOODS

Does it get any more challenging as a food safety and quality guardian in a high-risk food facility? A combination of the lack of consumer kill steps and the threat pests can significantly amplifying environmental contamination.

A zero-tolerance culture will be critical to ensure pest prevention. Should a single house fly land on a food contact surface between pre-operative cleaning and sanitizing and manufacturing, there could be as many as 37 pathogens waiting to contaminate your high-risk food. With 300,000 to 1.5M bacteria and viruses on a single house fly, you need not take that risk.

Frequent training is occurring in your organization. Our Close the Gaps™ Training Programs have formed better habits and better culture for many of our customers.

CO-PACKERS / PRIVATE LABELING - If you are producing under someone else’s label, you are likely required to provide third party certification to ensure your customer’s brand will not be compromised. Your customers want to ensure that you are protecting their products from brand damaging events.

Pharmaceutical & Bio-pharmaceutical Manufacturing

Let's face it, compliance with your cGMPs and SOPs are critical to your operation. Pests and documentation are no exception to this fact. You need a company that understands the importance of both to prevent non-conformance and non-compliance.

Critical care must be taken to ensure the safety of your products and brand. Even though your clean rooms have separate plenums and preventive maintenance with filtration, tiny insects and arthropods sometimes make it through your defenses into your production areas.

Discover how FDB’s granular zone monitoring and document control systems may help protect your products and brand.

CO-PACKERS / PRIVATE LABELING - If you are producing under someone else’s label, you are likely required to provide third party certification to ensure your customer’s brand will not be compromised. Your customers want to ensure that you are protecting their products from brand damaging events.

Organically Certified Manufacturing

Whether it’s food, beverages, supplements, cosmetics or other products that you manufacture under Organic Certification, you must prove that pesticides did not come in contact with your products.

Critical thinking of your Organically Certified operation with an eye towards pest prevention and monitoring is critical to reduce or even eliminate pesticide use.

What happens when harmful pests do invade your Organically Certified facility? There must be carefully executed and documented steps to ensure:

· Your Organic products do not ever come in contact with pesticides.

· Your Organic Certifying Auditing Body is satisfied with the actions taken to eliminate the pests that have infiltrated.

· The end consumer has complete confidence that your Organic products produced by your facility, are never compromised.

Food and Drug and the Bug utilizes a stringent Organic Action Chain procedure, to ensure maximizing pest prevention effectiveness, while ensuring that your Organic Certifying Audit Body and the end consumer are satisfied with the process.

CO-PACKERS / PRIVATE LABELING - If you are producing under someone else’s label, you are likely required to provide third party certification to ensure your customer’s brand will not be compromised. Your customers want to ensure that you are protecting their products from brand damaging events.

BAKERIES

Our Founder has a nickname phrase for bakery manufacturing sites; “The Superbowl of Pest Challenges.” The many reasons for his whimsical phrase are as follows:

Airborne ingredients, such as flour and other milled grains get into electrical boxes, conduits, control panels and processing equipment, they become difficult to reach and thus difficult to clean, therefore difficult to control. German cockroaches, stored product beetles and moths, often feed and breed in these challenging areas.

DESSERT BAKING

If you are a dessert bakery, the above is a challenge enough for you, then add the difficulty of cleaning butter-fats, sugary substances and baked on cakes, brownies and other desserts in pan wash areas. Pan wash areas are humid environment that pests love. Add stray foods to an already tropical area and pest populations grow exponentially.

HOUSE MICE!

If you only needed one tenth (1/10th) of an ounce of food per day to survive and could live your whole life and as well as future generations in a bag of raw ingredients, you would be considered quite fortunate! Every crumb, every spill from a fork truck puncturing a bag of ingredients, every missed piece of processing equipment in the Master Sanitation Schedule are “grocery stores” for the house mouse. There are infinite sources of heat, corners, shadows and holes in baking manufacturing; all the favorite and safest places for house mice to thrive.

WATCH THOSE SPICES!

If spices are a large part of your baking process, it is very important to ensure their proper rotation and to monitor them with pheromone lures. Constantly check dates and keep them properly sealed. A cigarette beetle can enter a 32nd of an inch gap and can tear through ingredient bags. Their larvae are hungry and very much enjoy dried spices such as basil and paprika and the like.

CO-PACKERS / PRIVATE LABELING - If you are producing under someone else’s label, you are likely required to provide third party certification to ensure your customer’s brand will not be compromised. Your customers want to ensure that you are protecting their products from brand damaging events.

MEDICAL DEVICE MANUFACTURING

Let's face it, compliance with your cGMPs and SOPs are critical to your operation. Pests and documentation are no exception to this fact. You need a company that understands the importance of both to prevent non-conformance and non-compliance.

Critical care must be taken to ensure the safety of your products and brand. Even though your clean rooms have separate plenums and preventive maintenance with filtration, tiny insects and arthropods sometimes make it through your defenses into your production areas.

Discover how FDB’s granular zone monitoring and document control systems may help protect your products and brand.

CO-PACKERS / PRIVATE LABELING - If you are producing under someone else’s label, you are likely required to provide third party certification to ensure your customer’s brand will not be compromised. Your customers want to ensure that you are protecting their products from brand damaging events.

Seafood Manufacturing

VALUE ADDED COOK FACILITIES have the highest pest pressures of all seafood plants. Some of the reasons for this are:

Breading, oil, spices, heat and fragrance signatures all contribute to higher pest pressures. Cockroaches, house mice, rats, ants and filth flies are at the top of that list. Value added seafood facilities have many of the common pest challenges than bakeries do. For more information see Bakeries

HIGH RISK SEAFOOD - Must have a zero-tolerance culture in pest prevention. There must not be any room for a lackadaisical attitude in your organization or your pest control provider.

FILTH FLY pressures are very high during warmer months. Odors from trash areas are highly attractive to blow and house flies. Reducing odors, through sanitation and brisk trash removal are helpful measures. Timely implemented rotation of residual fly treatments also reduces filth fly populations at the exterior trash areas of the facility.

Frequent training is occurring in your organization. Our Close the Gaps™ Training Programs have formed better habits and better culture for many of our customers.

CO-PACKERS / PRIVATE LABELING - If you are producing under someone else’s label, you are likely required to provide third party certification to ensure your customer’s brand will not be compromised. Your customers want to ensure that you are protecting their products from brand damaging events.

MEAT & POULTRY MANUFACTURING

Whether you are a custom portioning, value added, high-risk, canned or other meat producer you are governed by the United States Department of Agriculture (U.S.D.A.)

THE U.S.D.A. has very low tolerance for pests, especially in production areas. It is no wonder, as pests significantly amplify environmental contamination, especially on high-risk meat products. Our Founder has been asked to consult and mediate for meat production firms on several occasions to assist them with corrective actions from pest violations and U.S.D.A. shutdowns.

High risk meat & poultry must have a zero tolerance culture in pest prevention. There must not be any room for a lackadaisical attitude in your organization or your pest control provider.

Filth fly pressures are very high during warmer months. Odors from trash areas are highly attractive to blow and house flies. Reducing odors, through sanitation and brisk trash removal are helpful measures. Timely implemented rotation of residual fly treatments also reduces filth fly populations at the exterior trash areas.

CO-PACKERS / PRIVATE LABELING - If you are producing under someone else’s label, you are likely required to provide third party certification to ensure your customer’s brand will not be compromised. Your customers want to ensure that you are protecting their products from brand damaging events.

BEVERAGE MANUFACTURING & HANDLING

At critical filling points, flying insects, German cockroaches, ants and other insects are a threat to your products safety and your brand.

Salvage areas are often a target for filth flies, rodents and other pests seeking nutrition. Damaged finished goods in your storage areas are often a feeding spot for many structural invading pests. What methods are you using for best practice, pest prevention in salvage areas? This is often a training point for your employees to improve their behavior in the salvage areas.

CRAFT BREWERS - Many of you have likely rented a space that offers reasonable rent. Structurally, these spaces are often porous and offer pest harborage.

Your grains are highly attractive to rodents and stored product beetles and moths. Did you know that stored product beetles can change the character and flavor of your beer, as well as shorten shelf life?

Fruit flies are often present due to the gases rising from the yeasts that attract them. Intensive and detail cleaning is a must in your environment.

JUICE, ENERGY DRINK & SODA MANUFACTURING - Your customers find your products, sweet and delicious. Pests find your products the same way.

Phorid flies (mausoleum fly) often feed and breed in damaged goods because of the nature of the moisture and protein content.

WATER BOTTLERS - Water purity and safety are the concerns of your consumers. Water, as the “elixir of life” offers pests a good place to live and harbor for their survival.

CO-PACKERS / PRIVATE LABELING - If you are producing under someone else’s label, you are likely required to provide third party certification to ensure your customer’s brand will not be compromised. Your customers want to ensure that you are protecting their products from brand damaging events.

Dairy Manufacturing

Producing your micro-sensitive dairy products, safe and pure for the public is daunting enough. When pests that are pathogen laden invade your environment, your concern is compounded. Whether it's milk, yogurt, cheese or other dairy products, they are all high-risk foods to varying degrees. Many structurally invading pests are attracted to dairy products.

SMALL FLY SPECIES: You may be experiencing a number of small fly species in your environments. The use of water for cleaning combined with foods and liquids and proteins are a haven for the varieties of phorid, cheese skipper, drain, fruit, sphaerocerid and other species types. Intensive cleaning and sanitizing of not only floor drains and other micro-environments are crucial in preventing small flies in your dairy operation. With 300,000 to 1.5M bacteria and virus cells on each fly, it is crucial to prevent them from gaining entry to your production spaces.

COMMENSAL RODENTS: The house mouse and Norway rat are two highly successful mammals that live off humankind’s carelessness. Your operation must be continually scrutinized for opportunities to avoid these brand damaging rodents to enter your facility. They must be carefully excluded structurally and from suppliers delivering them to you. Expert training is recommended to keep your team in pest exclusion mode at all times.

CO-PACKERS / PRIVATE LABELING - If you are producing under someone else’s label, you are likely required to provide third party certification to ensure your customer’s brand will not be compromised. Your customers want to ensure that you are protecting their products from brand damaging events.

Warehousing & Logistics

WAREHOUSING & LOGISTICS - Provides many opportunities for the ultimate in opportunists, pests.

Bulk transportation alone is a major source of “hitch-hiking” pests looking to “thumb a ride” to and from your facility. You are likely in the middle of the food supply chain, housing thousands of SKUs, with a multitude of trailers transporting goods in and out at a feverish rate.

Shadows from pallets and pallet racks make an ideal “safe zone” for all sorts of pests. Spills from torn ingredient bags, totes, super-sacks and the like, provide much of the food needed for rodents and insect pests to thrive.

Pest exclusion, rotation and sanitation are all ways to help prevent pests from becoming a major problem in your warehouse. We provide custom Warehouse & Logistics Pest Prevention Training to assist you with these prevention measures.

CO-PACKERS / PRIVATE LABELING - If you are producing under someone else’s label, you are likely required to provide third party certification to ensure your customer’s brand will not be compromised. Your customers want to ensure that you are protecting their products from brand damaging events.

CANDY & CONFECTIONERY, NUTS, MIXED SNACK FOODS

Let's face it, your facility is sweet, really sweet! Sugar, are there any such thing as ants, stinging insects and flies and rodents not attracted to sugar?

Nuts and seeds are highly susceptible to stored product moths and beetles. Rodents are highly attracted to your facility also. Without proper training and guidance to understand the resources needed for detailed sanitation and ongoing structural repair, you may find yourself grappling with serious pest issues.

Your raw commodities are especially vulnerable, as they often bring all stages of stored product pest life cycles.

Of course, each and every facility has different pest risk profiles. Location, environmental surroundings, company culture and resources, what is produced, and many other factors need to be considered to provide proper pest risk mitigation.

CO-PACKERS / PRIVATE LABELING - If you are producing under someone else’s label, you are likely required to provide third party certification to ensure your customer’s brand will not be compromised. Your customers want to ensure that you are protecting their products from brand damaging events.

PACKAGING MANUFACTURING

Whether you are an aseptic, thermoforming, glass or plastic bottle, cans, polybag, film or other food or medicine contact packaging manufacturer, your products are considered the same as food by the FDA and by your customers that you produce packaging for.

If you are a paperboard, corrugated or other non-food contact packaging manufacturer, your products are still likely considered the same as the food by the customers you provided packaging for.

All packaging requires stringent protection from pest infiltration. Physical exclusion practices and knowledge are a must to protect your brand.

CO-PACKERS / PRIVATE LABELING - If you are producing under someone else’s label, you are likely required to provide third party certification to ensure your customer’s brand will not be compromised. Your customers want to ensure that you are protecting their products from brand damaging events.

Copyright © 2026 Food and Drug and the Bug LLC - All Rights Reserved.